The OEM part number uniquely identifies a spare part. So, when you search for any spare part, you typically need to know its OEM part number; otherwise you risk of buying the wrong item. Finding the OEM part number of a spare part is not always easy. Normally, you need to have the illustrated parts diagram (a.k.a. parts manual) of your machine which shows the schematics of the parts which the machine consists of. Unlike the Operator's manual which you may find into the box of a brand new machine, the parts manual is not a booklet that you get with your machine. Indeed, if you have bought a used machine most probably you won't get any manual, at all.

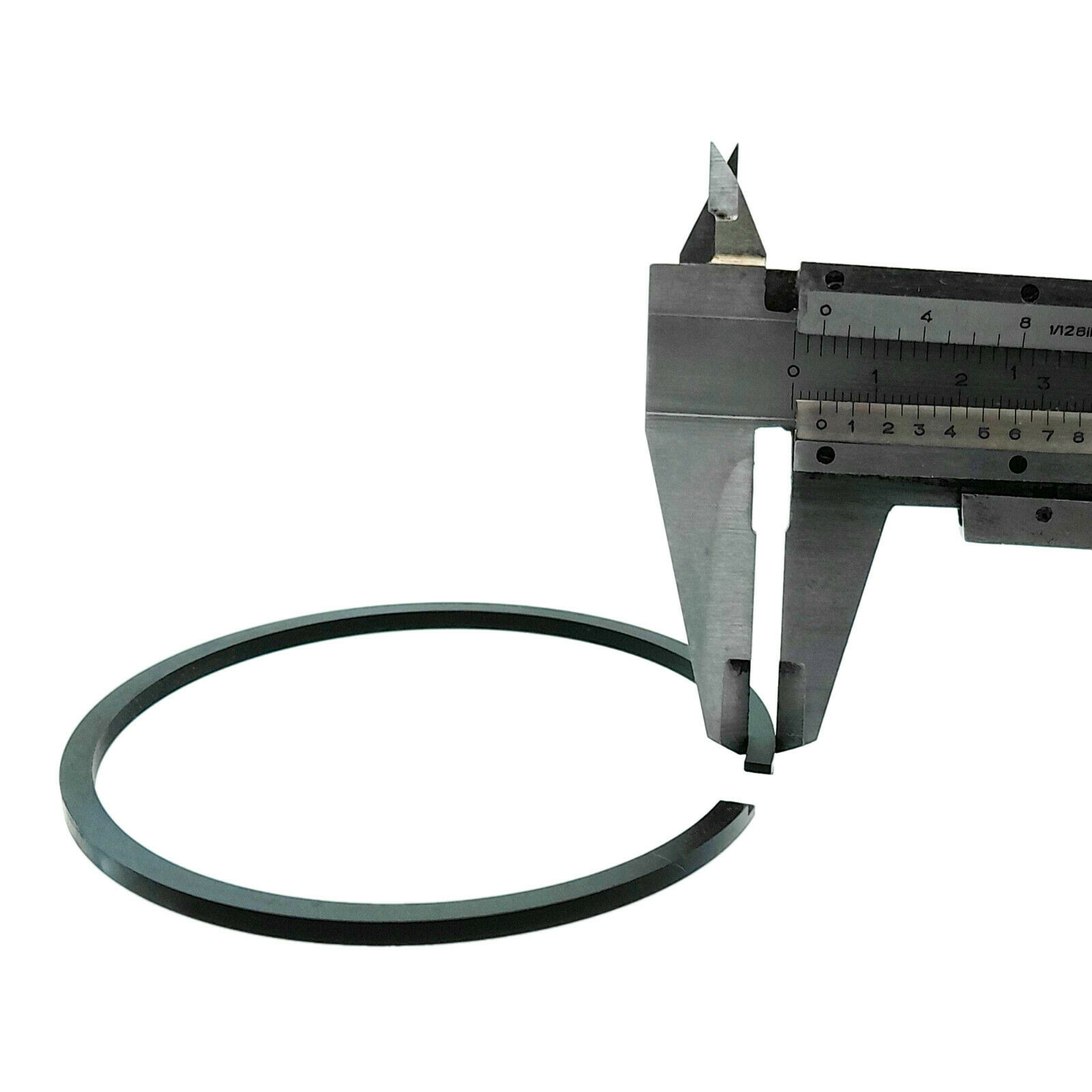

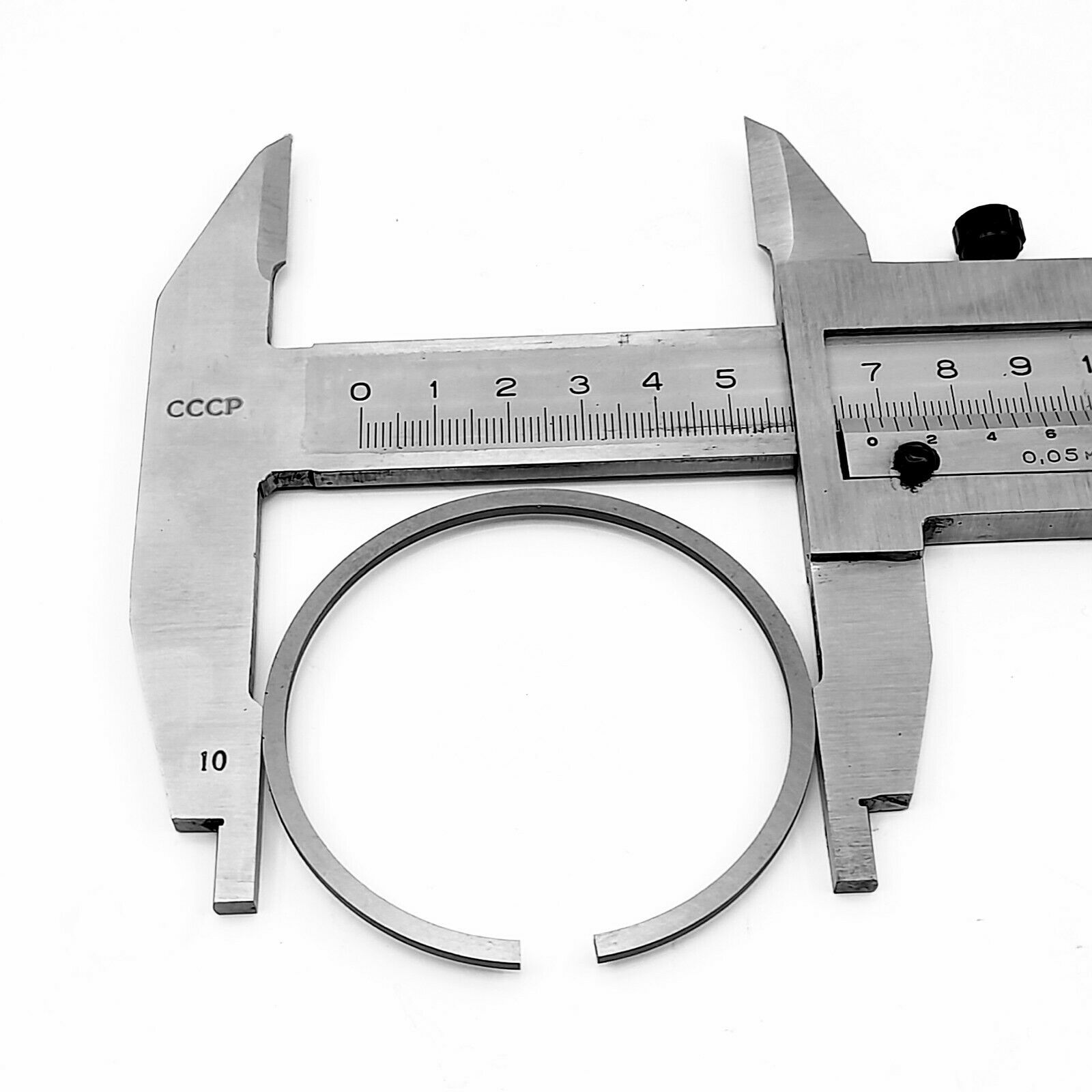

Fortunately, speaking for piston rings, you just need to know their sizes and not the OEM part numbers so as to find replacement piston rings. However, it is crucial to take correct and accurate measurements, as even a 0.05mm difference matters. All you need to have is just a vernier caliper, preferably a digital one, which is generally a cheap tool that can be found in any tool shop.

Piston ring diameter

First of all, you need to measure the diameter of your piston ring which typically matches the diameter of the cylinder. Normally, you need a circometer for that purpose which is an expensive precision tool, and it is used by professionals who take many measurements per day.

First of all, you need to measure the diameter of your piston ring which typically matches the diameter of the cylinder. Normally, you need a circometer for that purpose which is an expensive precision tool, and it is used by professionals who take many measurements per day.

Fortunately, you can use your cheap vernier caliper to measure the diameter of your piston instead of the piston ring diameter. The measurement for the diameter should be taken down at the skirt of the piston. Of course, the piston diameter is a bit less than the cylinder diameter; otherwise the piston could not work. For example, if your cylinder diameter is let's say 78mm, the piston diameter is something like 77.97mm. So, the diameter of the piston rings to fit that piston is actually 78mm. The piston ring manufacturer has also taken into account the gap tolerance in order to prevent the ends of the piston ring from butting together as the piston ring expands when the engine approaches operating temperature. The gap tolerances depend on the diameter of the piston ring.

Piston ring axial thickness

The axial thickness of the piston ring can be easily measured with the vernier caliper. The axial thickness has specific nominal values:

The axial thickness of the piston ring can be easily measured with the vernier caliper. The axial thickness has specific nominal values:

- 1.0 mm

- 1.2 mm

- 1.5 mm

- 1.59 mm (1/16")

- 1.98 mm (5/64")

- 2.0 mm

- 2.38 mm (3/32")

- 2.5 mm

- 3.0 mm

- 3.17 mm (1/8")

- 3.5 mm

- 3.97 mm (5/32")

- 4.0 mm

- 4.5 mm

- 4.76 mm (3/16")

- 5.0 mm

- 5.5 mm

- 5.55 mm (7/32")

- 6.0 mm

- 6.35 mm (1/4")

- 6.5 mm

The sizes for American, British and Swedish machines are usually expressed in inches. So, if the axial thickness is measured a bit more than 1.5 mm then it must be 1.59 mm or 1/16". The same happens for axial thicknesses of 3.0 mm and 3.17 mm (1/8"), and axial thicknesses of 4.5 mm and 4.76 mm (3/16"). On the contrary, a 2.0 mm thick ring can also fit a piston groove of 1.98 mm (5/64"), and a 4.0 mm thick ring can also fit a piston groove of 3.97 mm (5/32"), and vice versa.

Piston ring radial thickness

The radial thickness of the piston ring can be easily measured with the vernier caliper, as well. However, this applies to a brand new piston ring. For a used piston ring this measurement will not give the correct number, as the radial thickness of a heavily used piston ring will be found much less than the nominal radial thickness. For this purpose, it is recommended to measure the depth of the corresponding piston groove by using the depth probe of the vernier caliper. Of course, the radial thickness of a piston ring must be less than the depth of the groove it fits. However, knowing the groove depth you can determine if your groove can accommodate a piston ring which has the appropriate diameter and axial thickness.

Common mistakes

There are some common mistakes that you should avoid when measuring a piston ring; otherwise you risk of buying the wrong item:

| Measuring the diameter of the piston by using tools other than a vernier caliper, such as a ruler, will give you inaccurate numbers. |  |

| Measuring the diameter of the piston near the head where the piston rings are placed will give you inaccurate numbers. |  |

| Measuring the diameter of the uncompressed piston ring with a vernier caliper does not make sense. |  |

| Measuring the diameter of the compressed piston ring with a vernier caliper will give you inaccurate numbers. |  |

| You bought a brand new piston ring, but its gap when placed into the cylinder is too large as it happened with your old piston ring. This means that your cylinder is worn and you need to rebore it so as to install an oversize piston. Before replacing the piston or the piston rings, make sure that the wear of the cylinder is not large enough so that you need an oversize piston. |